Rubber Bellows

Custom

Rubber

Molding

Custom rubber bellows and boots play a crucial role in various industrial systems, serving as flexible seals that protect against dust and other environmental elements. At TechnoXperts, we specialize in the precise manufacturing of custom rubber bellows and boots, ensuring that our products meet the most stringent requirements. Our commitment to quality guarantees that each product functions effectively within its intended application.

Material Selection

Custom-compounding elastomers and conductive fillers for optimal performance.

Moulding

Precision moulding of gaskets and components using advanced techniques.

Quality Testing

Rigorous testing to ensure compliance with industry standards before delivery.

Custom Rubber Solutions

We utilize advanced techniques and the latest materials to produce high-quality bellows and boots that withstand a range of conditions. Our custom rubber solutions are designed to protect against various elements, including:

- Dust

- Water

- Oil

- Grease

- Acids

- Bleaches

- Spatter and pressure

- Moisture

- Chemicals

- UV exposure

- Other environmental factors

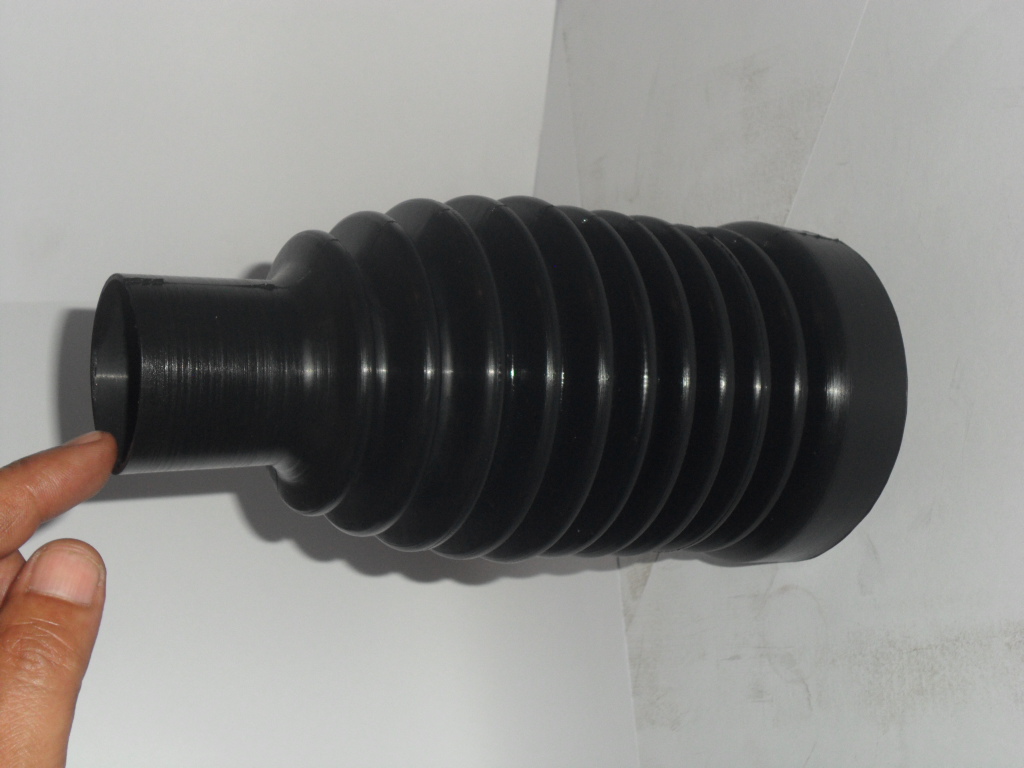

Convoluted Rubber Bellows and Boots

TechnoXperts also offers convoluted rubber bellows and boots, which are versatile seals adaptable for a wide range of applications across various industries. These intricate seals can be custom-designed to feature varying wall thicknesses and configurations, providing solutions that traditional styles cannot offer.

Common applications for our convoluted rubber bellows and boots include steering components, pumps, cylinders, and expansion joints for HVAC systems. We manufacture these products using a diverse selection of rubber materials and compounds, including:

- Natural Rubber (NR)

- Silicone Rubber (VMQ)

- Neoprene® (CR)

- Polyisoprene (IR, NR)

- Styrene-Butadiene (SBR)

- Butyl (IIR)

- Ethylene-Propylene (EPDM)

- Nitrile (Buna-N, NBR)

- Fluorosilicone (FVMQ)

- Viton® (FKM)

This extensive material range ensures that we can meet the unique demands of each application while providing reliable, long-lasting performance.