Production Technology

Production Techniques.

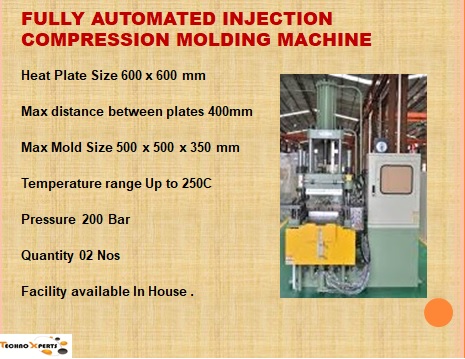

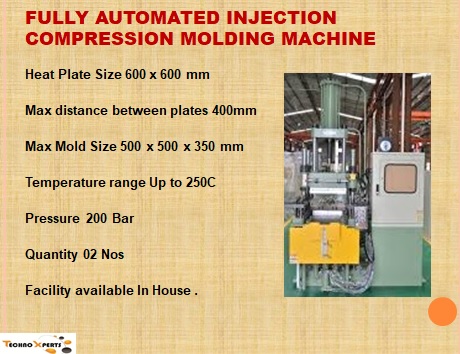

At TechnoXperts, we utilize a variety of advanced production techniques for manufacturing high-quality rubber products. Our capabilities include compression molding, transfer molding, and thermoplastic injection molding, ensuring flexibility and efficiency in our manufacturing processes. Each technique is chosen based on the specific requirements of the product, allowing us to deliver tailored solutions that meet our clients’ needs.

Our state-of-the-art mold designing and precision mold manufacturing are integral to our production process. By employing advanced technology and skilled craftsmanship, we ensure that our molds are designed for optimal performance and longevity. This focus on quality allows us to maintain tight tolerances and consistency across all our rubber products.

Material Selection

Custom-compounding elastomers and conductive fillers for optimal performance.

Moulding

Precision moulding of gaskets and components using advanced techniques.

Quality Testing

Rigorous testing to ensure compliance with industry standards before delivery.

Molding Processes

The principal molding processes for rubber at TechnoXperts include:

- Compression Molding

- Transfer Molding

- Injection Molding

In all three processes, curing (vulcanizing) occurs directly within the mold, which represents a significant advancement over traditional methods that required separate vulcanizing steps. This integration of heating and pressurizing ensures that the rubber obtains the desired die shape efficiently, enhancing both productivity and quality. Our commitment to modern production techniques ensures that we can meet the demands of various applications while maintaining high standards of performance and reliability